-

AlexanderCác nhà cung cấp đáng tin cậy

AlexanderCác nhà cung cấp đáng tin cậy -

LouisThật là một niềm vui khi làm việc với anh.

LouisThật là một niềm vui khi làm việc với anh.

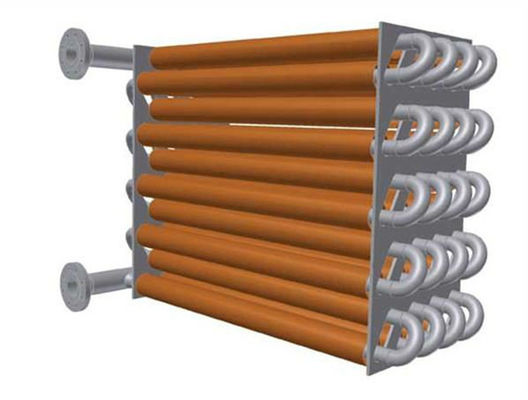

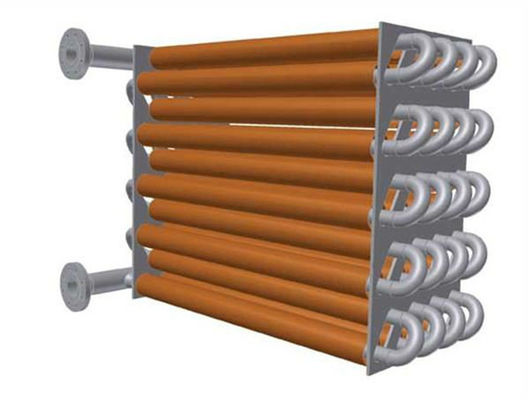

Bộ trao đổi nhiệt Economizer lò hơi khí thải với ống cánh tản nhiệt cho sản xuất hơi tối đa 120t/h và bảo hành 1 năm theo kiểu tuần hoàn tự nhiên

Liên hệ với tôi để lấy mẫu miễn phí và phiếu giảm giá.

whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Nếu bạn có bất kỳ mối quan tâm nào, chúng tôi cung cấp hỗ trợ trực tuyến 24 giờ.

x| Kiểu | tuần hoàn tự nhiên | Kết cấu | Ống lửa và ống nước |

|---|---|---|---|

| Áp lực | Áp suất thấp / cao | Sản xuất hơi nước | Tối đa. 120T/h |

| Phong cách | Thẳng đứng | Nhiên liệu | Than / Gas / Đốt than / Nhiệt nước |

| Đầu ra | Nước nóng / Hơi nước | Vật liệu | Thép carbon, thép không gỉ, thép hợp kim |

| tiêu chuẩn vật liệu | ASTM, EN hoặc ISO, v.v. | Phạm vi trọng lượng | Tối thiểu: tối đa 10 tấn |

| Quá trình luyện kim | EF+LF + VD | Quá trình | Vật liệu-> Ingot -> nóng/lạnh-> Xử lý nhiệt (bình thường hóa+ ủ) -> Kiểm tra -> Gia c |

| Tiêu chuẩn Ut | ASTM A388 hoặc EN10228, v.v. | Loại trao đổi nhiệt | Bộ tiết kiệm ống H-Fined |

| Loại ống | Double H | ||

| Làm nổi bật | Economizer lò hơi cho sản xuất hơi tối đa 120t/h,Bộ trao đổi nhiệt bảo hành 1 năm,Economizer khí thải tuần hoàn tự nhiên |

||

Máy tiết kiệm nồi hơi là các thiết bị trao đổi nhiệt hiệu quả cao với các ống có vây được thiết kế để làm nóng chất lỏng (thường là nước) mà không vượt quá điểm sôi của chất lỏng.Chúng tôi sản xuất ba loại nồi hơi tiết kiệm:

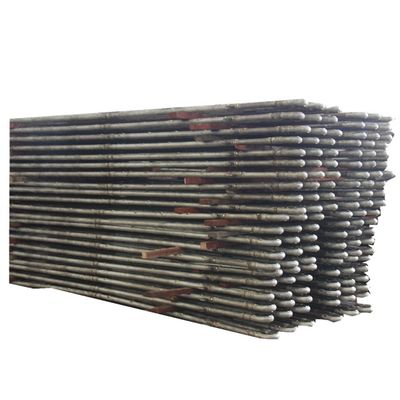

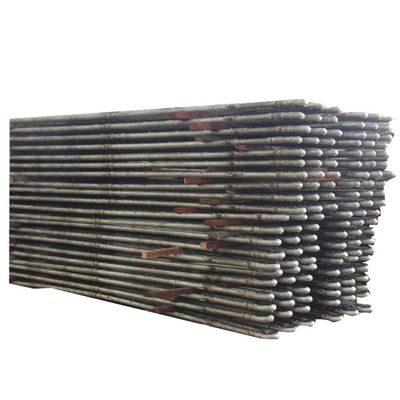

- Máy tiết kiệm ống trần

- Máy tiết kiệm ống có vây H

- Máy tiết kiệm ống có vây xoắn ốc

Máy tiết kiệm ống có vây H là một thiết kế đặc biệt hiệu quả bao gồm các ống có vây H. So với các máy tiết kiệm ống trần, các mô hình ống có vây H cung cấp một số lợi thế:

- Khu vực trao đổi nhiệt tăng

- Số lượng ống cần thiết giảm

- Khu vực lưu lượng khí khói mở rộng để giảm tốc độ lưu lượng và mài mòn

- Có sẵn trong cấu hình ống có vây H kép để tăng độ cứng trong các hàng ống dài

Máy tiết kiệm có vây xoắn ốc đại diện cho sự đổi mới thiết kế mới nhất của chúng tôi, với các ống vây xoắn ốc hiệu quả giải quyết các vấn đề mài mòn và kéo dài tuổi thọ.

| Mô tả | Máy tiết kiệm nồi hơi |

|---|---|

| Vật liệu | Thép hợp kim, thép carbon, SA210C, SA213T22, v.v. |

| Tiêu chuẩn vật liệu | ASTM, EN hoặc ISO vv. |

| Cấu trúc | Tùy chỉnh |

| Trọng lượng | Ít nhất: 10 tấn Tối đa: 1000 tấn |

| Quá trình nóng chảy | EF+LF + VD |

| Quá trình | Vật liệu→Ngô → Lăn nóng/ lạnh→ Điều trị bằng nhiệt (Thông thường hóa + làm nóng) → Kiểm tra →Làm máy thô→UT →Điều xử lý bằng nhiệt thứ hai →Làm máy hoàn thiện →Kiểm tra |

| Tiêu chuẩn UT | ASTM A388 hoặc EN10228, vv |

- Báo cáo kiểm tra va chạm và tính toán độ bền với thông tin về vật liệu áp dụng

- Báo cáo NDT 100% (kiểm tra không phá hủy) của tấm thép, ống và điện cực

- Báo cáo kiểm tra thử nghiệm tia X, tia γ và chất lỏng xuyên (đá hàn) để đảm bảo chất lượng nồi hơi hoàn chỉnh

- Báo cáo thử nghiệm thủy lực để xác minh áp suất làm việc tiêu chuẩn và an toàn