-

AlexanderCác nhà cung cấp đáng tin cậy

AlexanderCác nhà cung cấp đáng tin cậy -

LouisThật là một niềm vui khi làm việc với anh.

LouisThật là một niềm vui khi làm việc với anh.

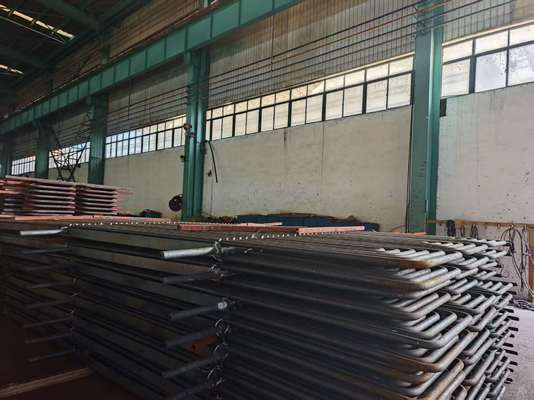

Anti Corrosion Carbon Steel Superheater - Coal Fired CFB Power Plant Boiler Parts

Liên hệ với tôi để lấy mẫu miễn phí và phiếu giảm giá.

whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Nếu bạn có bất kỳ mối quan tâm nào, chúng tôi cung cấp hỗ trợ trực tuyến 24 giờ.

x| Đặc trưng | Chịu nhiệt độ cao, chống ăn mòn, bền, có thể tùy chỉnh | Vật liệu | Thép cacbon, thép hợp kim, thép không gỉ, hợp kim niken, Hastelloy, Inconel, Incoloy, Duplex Steel, |

|---|---|---|---|

| Chiều dài cuộn dây | tùy chỉnh | Vật liệu cuộn dây | Thép cacbon, thép hợp kim, thép không gỉ, hợp kim niken, Hastelloy, Inconel, Incoloy, Duplex Steel, |

| Xử lý bề mặt | Sơn, ủ, phủ bột, đánh bóng | Hình dạng | Đẳng, hình chữ U, Serpentine |

| Ứng dụng | Nồi hơi, Nhà máy điện, Hóa dầu, Nhà máy lọc dầu, Hóa chất, Giấy & Bột giấy, Dệt may, Đường, Dược | Kích cỡ | tùy chỉnh |

| Điều trị bề mặt cuộn dây | Sơn, ủ, phủ bột, đánh bóng | Loại cuộn | Trần truồng |

Anti Corrosion Carbon Steel Superheater - Coal Fired CFB Power Plant Boiler Parts

Description

For power plant boiler, it is a crutial way to increase thermal economy of thermal power station by improving parameter of superheated steam. The increase of superheated steam parameters are limited by metal materials. The design of superheaters must make sure that the temperature of outer wall of heating surface pipes is lower than allowable temperature of oxidation resistance of steel, and meanwhile make sure its mechanical strength. with the development of metal material used in boilers, power station boilers in our country already generally apply high pressure, high temperature(9.8MPa, 540 degrees) and superhigh pressure parameters(13.7 MPa, 540 and 555 degrees), and have developed subcritical pressure parameters(16.7MPa, 540 and 555 degrees). Now lots of boilers apply supercritical pressure parameters(24.5MPa, 540-570 degrees), and even very few units apply higher pressure and temperture parameters.

![]()

Application

use for heating saturated steam, steam temperature could be up to 900 degree C.

Superheater Capacity Upgrades to Increase Power Generation

Send us required technical data, such as steam capacity, presure, required temperature etc. We will design accordingly.

Differences

| Type | Advantages | Disadvantages | Supporting method |

| Pendant-type | 1.Firm structural support | 1. Flow blockage by condensed steam 2. Needs slow restart to purge the water that accumulates in the bottom. | supported from above |

| Inverted-type | 1.Proper drainage of the condensed steam | 1. Lack the structural rigidity, especially in high speed gas flow | Supported from below |

| Horizontal -type |

1. Proper drainage 2. Good structural rigidity. |

1. They do not view the flam directly so they are mainly from the convective type | Usually supported in the vertical gas ducts parallel to the main furnace. |